3-Way Catalytic Converters / Catalytic Mufflers

Three-Way Catalytic Converter – Performance

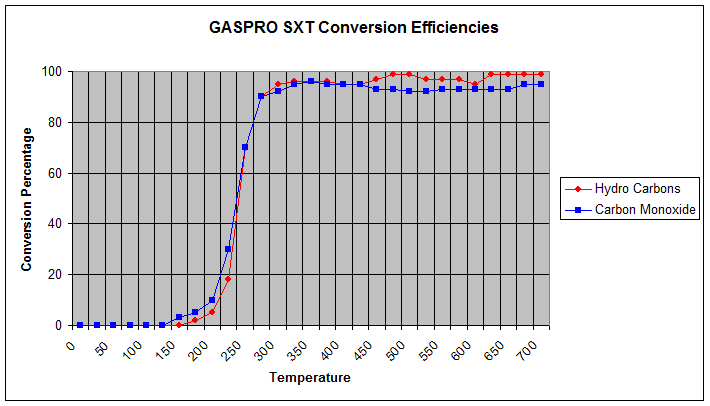

Emission reduction is dependent on engine maintenance, running on heavy to medium load and slightly leaning the engine carburetor jet to provide additional oxygen for increased catalyst activity. The following average exhaust gas emissions can be expected:

Carbon Monoxide (CO) = 70%-82%+

Hydrocarbons (HC) = 55%-88%+

Aldehydes (HCHO) = 70%-80%+

The gas engine should be in a very good state of condition with respect to tuning, repair and maintenance. All engine components and component tolerances should be well within the engine manufacturer specifications. The engine should not be consuming an unusual amount of lube oil. The ignition and carburetion systems should be operating properly and should be set to engine manufacturer specifications. A complete tune up prior to installation of the 3 way catalytic converter is recommended to minimize harmful exhaust emissions and provides good purifier operation and life. Ensure that the engine spark plug(s) are new and that the air cleaner element(s) are new and/or clean.

Attach the voltage meter set to millivolts (mV). Measure the millivolt signal from the oxygen sensor while the engine operates at a steady idle speed and at a constant load. Use this table to interpret the oxygen sensor voltages:

|

Millivolt Voltage (mV) |

Interpretation |

|

Less than 250mV |

Too lean |

|

250mV to 410mV |

Lean |

|

410 to 580mV |

Ideal for purifier operation |

|

580 to 800mV |

Rich |

|

Over 800mV |

Too Rich |